Thickness Measurement

Principle of Thickness Measurement

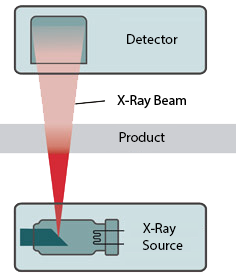

The radiometric thickness measurement is based on the partial absorption of ionizing radiation in matter. By selecting the energy of the x-ray source the measurement can be adapted perfectly to the material to be measured and the required measurement range.

On the other side of the material the intensity of the radiation that passes the strip is measured wit a suitable detector. The measured radiation intensity depends on the absorbing material (Al, Fe, Zn, etc.), on the energy of the radiation and on the thickness of the absorbing material:

I=Ioe-µd

Where:

- I is the intensity measured with the material present,

- Io is the intensity without material in the device,

- µ is the absorption coefficient,

- d is the thickness of the material.

For this reason the radiometric non-contact measurement method provides very precise thickness values at a very high measurement rate for automatic control and quality assurance. X-ray thickness gauges are therefore the first choice for online non-contact thickness measurement in production facilities e.g. rolling mills in the steel and aluminium industries.